Louvre windows are an efficient and sustainable natural ventilation solution, allowing twice as much air to circulate versus traditional window designs. Historically, they have been recognised as a popular fixture in warm tropical climates. However, the basic design of louvre windows has evolved considerably over time. These days, louvres can be seen as a design element as well as a technical device to utilize natural ventilation and temperature control. But as modern building projects need to fulfil a myriad of environmental, safety and security requirements, there are some big differences in performance between the louvre window products available in the market today.

By highlighting the key areas of performance differentiation, we aim to help specifiers and buyers to select the right louvre product for the right application.

Vital changes in building requirements

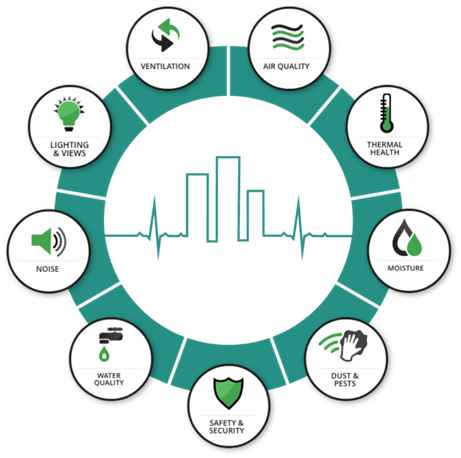

The Healthy Building Movement was initiated to support and improve the health and well-being of building occupants through innovations in design, construction, facilities, and operations. From this, the 9 Foundations for a Healthy Building were established that includes the following: air quality, dust and pest control, lighting and views, moisture, noise control, safety and security, thermal health, ventilation, and water quality.

In line with the 9 Foundations, the National Construction Code (NCC) has made changes to support the Healthy Building initiative. The NCC is Australia’s primary government agency that sets technical design and building construction regulations whilst adapting to climate, geological or geographic conditions. As a performance-based code, the NCC indicates the minimum requirements that building projects must comply to ensure overall safety, health, amenity, accessibility and sustainability. This is why there are variations in terms of quality and product performance of building materials, including window design.

Energy efficiency: a key factor in choosing window design

A building’s window style adds aesthetic value to its overall appearance. But given the thrust to promote a “healthy building”, it is highly recommended that the value of energy efficiency should also be considered. Windows serve as a major contributor in that aspect. In fact, an average home may lose as much as 30% of its heat or air-conditioning energy through inefficient window design.

Whilst cost may also be a driving factor with cheaper options at off-the-shelf prices, having an energy-efficient window design can produce significant monetary savings in the long run. For example, improved ventilation will reduce the costly need to use mechanical cooling systems. In terms of life-cycle cost, efficiently designed window systems are highly durable, last much longer, and help you conserve more energy whilst avoiding costly repairs and wasteful energy consumption.

Technological advancements have produced high-performing and attractive louvre window systems that perfectly address energy and cost efficiency concerns. More importantly, they function in compliance with the industry-level standards set by the NCC.

Whilst some louvre window products may be doing the bare minimum just to meet NCC’s requirements, Safetyline Jalousie aim to exceed expectations with higher performance ratings across all metrics.

Future-proof solutions for energy-efficient and healthy liveable spaces

The team behind Safetyline Jalousie are constantly looking at ways to evolve and develop louvre products and ventilation solutions that meet all of the modern environmental, safety and security standards, but are also innovative and adaptable for emergent requirements.

The new Safetyline Thermique louvre window is a cutting-edge solution designed to help clients meet their energy efficiency needs. It combines the advantages of Safetyline’s high free air and low air-infiltration windows with European thermal break technology. Featuring a reinforced polyamide louvre profile, the transfer of heat and cold across the window is minimised to reduce system U-values.

In an era of sustainable design, Safetyline Thermique allows architects and building designers to achieve performance compliance, improve energy efficiency, and deliver the provision of year-round comfort.

Another revolutionary innovation by Safetyline Jalousie is the SmartAir System – a pre-programmable and fully automated, turnkey louvre window solution with environmental, economic, and social benefits. Endorsed by CSIRO and Nabers, SmartAir has been developed in conjunction with Blue Squared Window automation to address the prevailing need for better indoor air quality, particularly in school and aged care settings in the wake of covid-19.

With SmartAir, Safetyline Jalousie louvres can be automated and integrated with sensor-activated control systems that monitor temperature, humidity, CO2 levels, and other environmental parameters. This improves air quality with natural ventilation whilst reducing the need for constant manual control, and reduces energy consumption by locking out AC when louvres are open. More importantly, it supports the creation of liveable indoor spaces that are aligned with the “healthy building” concept.

Key Performance Ratings – A comparison guide

To go into further detail, the graphic below provides an overview of Safetyline Jalousie’s other key areas of performance, and provides a comparison between Safetyline Jalousie’s louvre window systems versus conventional glass on glass louvre windows.

Given these outstanding ratings, Safetyline Jalousie’s louvre window systems provide top-of-the-line attributes that ensure higher performance levels to meet the most stringent building codes, and allows specifiers to use louvres in more applications than ever before.

But what do all of these numbers mean exactly?

• Ultimate and Serviceability Limit State

Safetyline Jalousie’s louvre windows are engineered to push the limits of strength and stability to withstand structural deflection from high wind pressures and service loads. From single level up to 100 levels, there is basically no building in Australia where Safetyline Jalousie louvres cannot be used.

• Protection from wind and water

Safetyline Jalousie’s louvre windows use weather-proof seals to ensure maximum protection against environmental elements, regardless of the height of the building.

• Acoustic performance

Safetyline Jalousie louvre windows are tested for acoustic rating in compliance with Australian Standard AS 1191-2002. With its improved sound insulation, the noise reduction is equivalent to loud traffic sounds diminished to the acoustic level of an average office. This makes Safetyline Jalousie louvres ideal for challenging projects under flight paths, on busy main roads, and backing onto train lines.

• Air infiltration

Often a metric that is overlooked in favour of U-Values is air infiltration. Air leakage into building interiors has a considerable impact on internal comfort levels and energy usage, consumption and costs. Safetyline Jalousie’s unique sealing system is comparable to a fixed pane window. By using Safetyline Jalousie louvres, which have a much higher air tightness figure than generic louvres (and the requirements of NCC2019), a building’s overall air tightness can increase by 20%, for a much tighter control of indoor air quality.

• Safety and security

In terms of glass and impact load weight, Safetyline Jalousie’s louvre windows are able to accommodate laminate glass with each blade sealed on 3 sides. This means there is no risk of falling shards of glass upon breakage, providing protection to the building’s occupants and to the public outside or below. The inbuilt security provided by the louvre bearer allows peace of mind when louvres are left open, even when a building is unoccupied.

• Balustrade / Fall prevention

Safetyline Jalousie louvres can be left open with no danger of falling through. With the opening width of just 106cm, this makes it impossible for even a child to fall through. It is safe and compliant to use at full heights on any project, including high-rise.

• Prefabricated products

Safetyline Jalousie’s prefabricated louvre windows will save you time and money on installation, and reduce waste materials on site. Our louvres are supplied as complete, glazed and framed units, manufactured to precise, predetermined dimensions to guarantee quality every time and provide efficiency in construction.

Minimising carbon footprint. Maximising opportunities.

Building and construction industry practitioners are presented with significant environmental opportunities during their involvement with the life functions of a building. Substantial benefits are available, by careful selection of building materials, components and assemblies and the practices used to incorporate them into a built environment. These benefits range from conserving resources to reducing environmental impacts, improving environmental quality and accruing subsequent savings through improved productivity and waste reduction.

Sustainability is a key element in Safetyline Jalousie’s core values to support the Australian government’s Net Zero initiative towards a greener future. This is reflected in every aspect of our business — from the design and the building materials to packaging and transport methods, and all the way down to the final product.

Our louvre window systems are constructed using highly durable aluminium. A metal known for being 100% recyclable and its strong resistance to corrosion, aluminium is also economically sustainable due to its low-cost recycling, high scrap recovery, and abundance of supply. In an Australian window industry first, Safetyline Jalousie have also introduced Hydro Reduxa Aluminium, a high quality, low-carbon aluminium that is produced using renewable energy sources such as hydropower. As a result, we are able to reduce the carbon footprint per kilogram of aluminium to approximately 4.0 — that’s less than a quarter of the global average.

Safetyline Jalousie provide healthier ventilation solutions for better living spaces with sustainable economic and environmentally friendly benefits. If you need assistance in terms of window design to comply with building requirements, we are here to help to ensure the best quality outcome, that will deliver proven value for money over a project’s lifetime, not just the short term.

For more information, email us at sales@safetylinejalousie.com.au. You may also contact us on 1300 863 350 or complete our online enquiry form here.